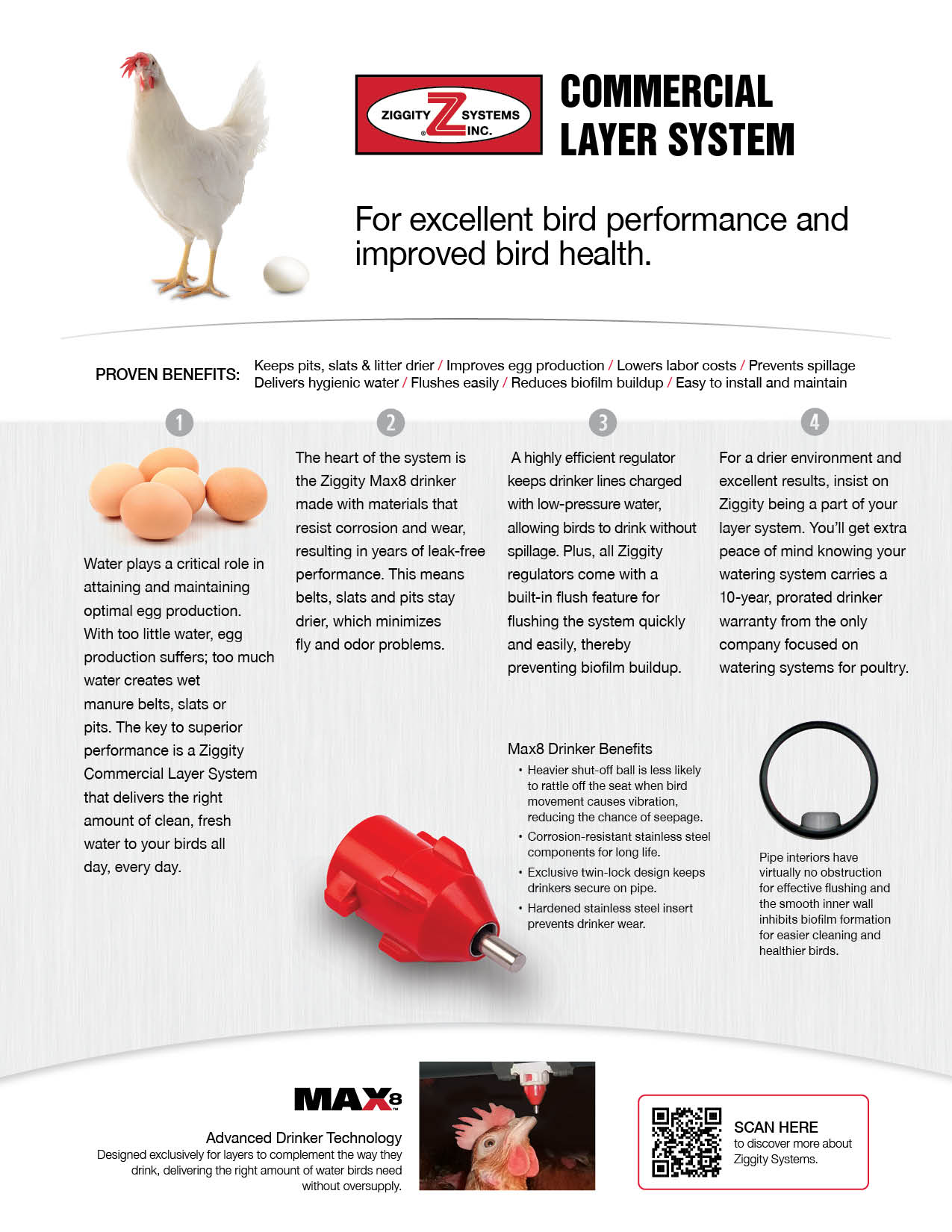

Ace TL Cage

Suitable for these bird applications:

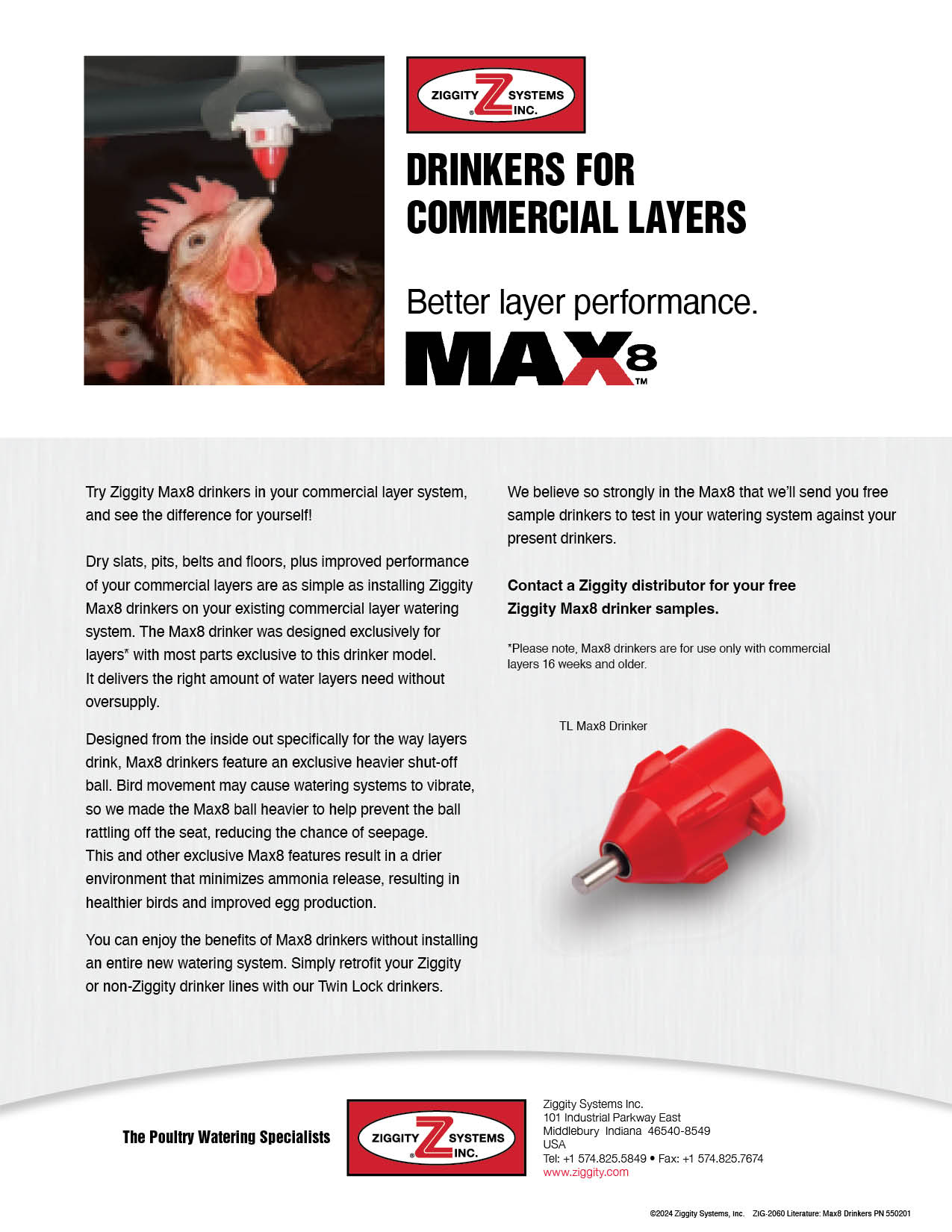

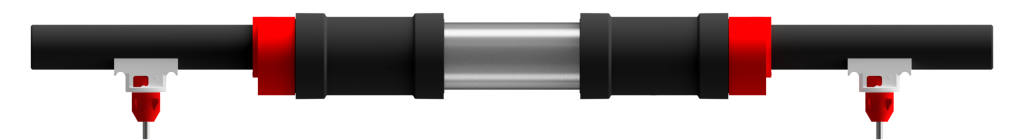

TL Max8 drinkers are radically different from standard drinkers, designed specifically for cage systems they help keep pits dryer. Internal components maintain a better seal for the way layers drink. Spills are minimized and pits stay dry.

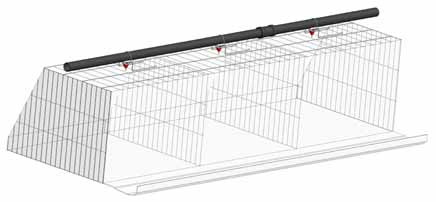

Maintain dry pits and excellent bird performance with Ziggitys Cage Layer System.

Deliver the right amount of fresh water to your birds with twin-lock (TL) drinkers and Ace 22.30 mm O.D. (0.88 in) black pipe all day, every day, while keeping pits and belts drier.

All Cage Systems

Download Literature (PDF):

EuroTier 2024

Hanover, Germany

November 12 – 15

Tool: Pipe Gap – Floor System Applications

GL1091Drinker Tool Guide

GL1092Field Fix: Inline Riser Assembly Sag

GL1093Ziggity Systems – André van Rij – Account Manager – Press Release

EMEA Account Manager Appointed by Ziggity Systems and Butterfly Concepts

— Ziggity Systems Inc., the maker of Ziggity brand poultry watering systems has developed helpful guidelines to help poultry producers with many common questions and needs regarding its watering systems. These guidelines are available on the company’s website, Ziggity.com.

To access these guidelines, which are designed to assist with best practices in product installation and usage, simply access the Ziggity website and find the “Guidelines” under the “Support” tab.

Guidelines available are subdivided under the headings, Field Fixes, Maintenance, Product Information, Product Installation and Warnings. Examples of guideline subjects are drinker manufacturing date codes, installation of heavy duty anti-roost cable and cord adjusters just to name a few.

“We want to make sure that our customers have ready access to important information that helps make them more efficient and successful,” said the company.

Another source of helpful information designed to help poultry producers maximize their performance can be found at the Poultry Watering U website. To visit Poultry Watering U click here.

Ziggity Systems Offers Helpful Online Guideline References

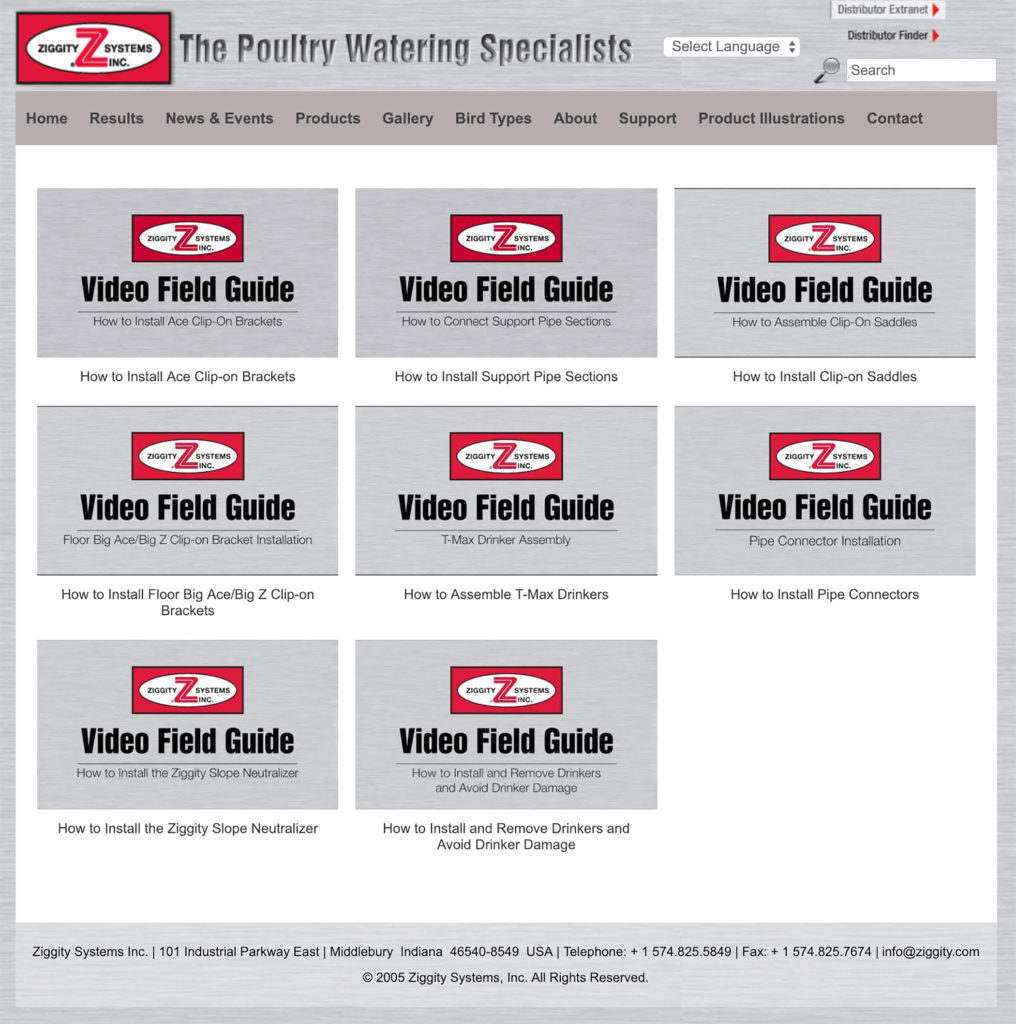

Ziggity Systems, Inc., the maker of Ziggity Brand poultry watering systems has added a library of helpful support videos for poultry producers on the company’s website, Ziggity.com. The growing video library is one element in Ziggity’s ongoing effort to help poultry producers maximize the benefits of their watering systems.

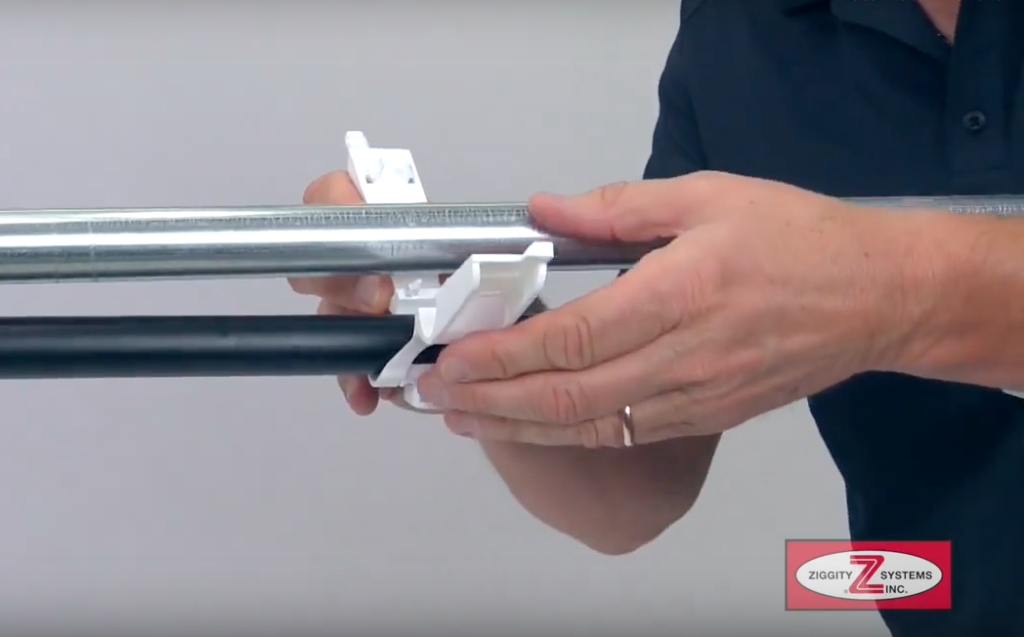

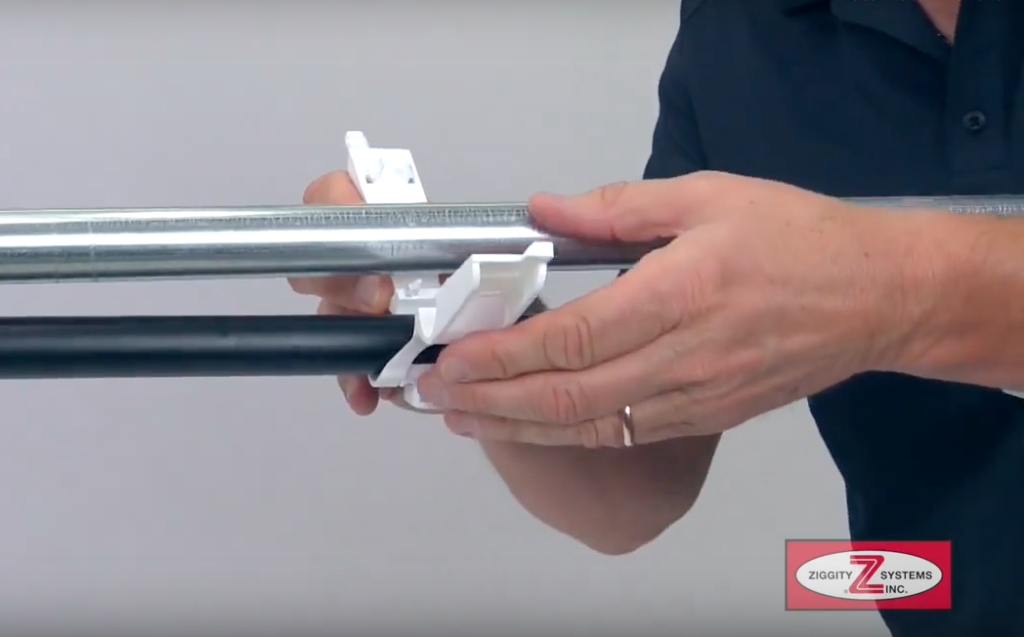

Two videos offer installation demonstrations for Clip-On brackets that are used to affix the water bearing pipe to the support pipe. One video shows installation of Clip-On brackets for Ace sized pipe while another video provides similar instructions for Big Ace/Big Z Clip-On brackets.

To view these videos and more, visit: https://ziggity.com/installation-videos/.

Another source of helpful information designed to help poultry producers maximize their performance can be found at the Poultry Watering U website at poultrywateringu.com.

Ziggity Systems Provides Support Videos for Clip-On Brackets

PN 4198 (for 1″ PVC pipe systems)

PN 4196 (for Ace pipe systems)

PN 4197 (for Big Ace pipe systems)

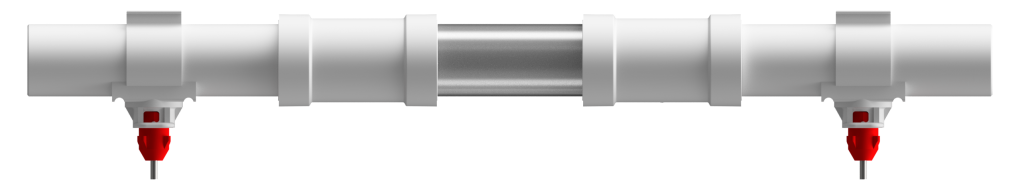

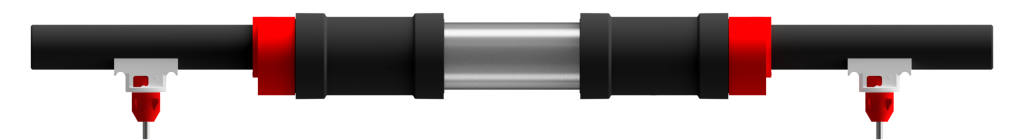

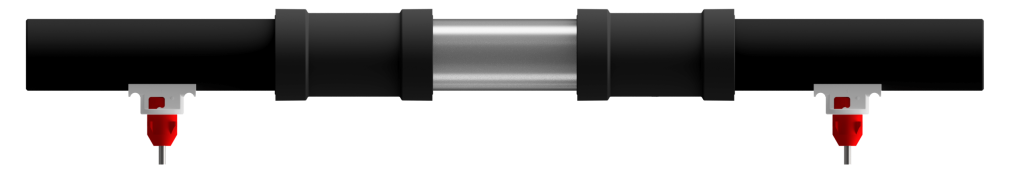

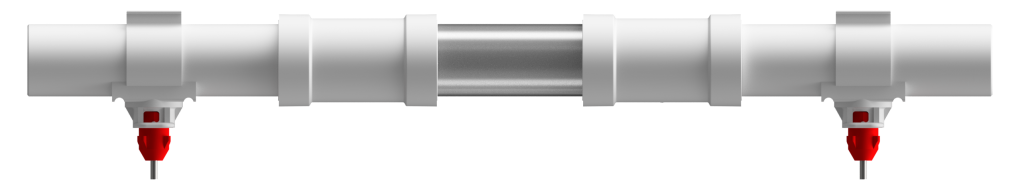

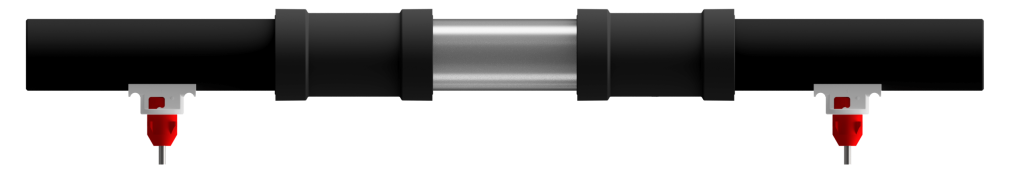

Ziggity Systems Inc. has made it easy for poultry producers to monitor and improve the quality of the water in their drinker lines with the transparent pipe kit. The kit is easily retrofitted onto existing Ziggity drinker lines. Once installed, water in the drinker lines can be visually monitored for contaminants such as biofilm, sediment and trapped air.

Ziggity Systems transparent pipe kit is an early warning indicator for: poor sanitation/biofilm, poor water filtration, trapped air, interventions that were not evenly dispersed or dissolved.

With the transparent pipe kit, debris getting past an ineffective filter can be observed, alerting producers to inspect the filtration system. During the production cycle when interventions are required, the transparent pipe kit allows for visual inspection inside the drinker line to confirm that the intervening materials are fully dissolved and evenly dispersed – which allows the producer to correct problems and improve the efficacy of the intervention.

The simple, easy-to-use water management tool is unique to Ziggity Systems and is compatible with any Ziggity Ace, Big Ace, Big Z or 1” PVC pipe system for all bird species and all bird applications – including floor and cage watering systems.

“A watering system is a key investment, and we urge producers to make use of this resource to be sure that investment is operating correctly for maximum performance,” according to the Ziggity technical team.

The transparent pipe kit can be installed directly out of the Ziggity regulator, directly into the Ziggity end assembly or any other location on the drinker line. They are available through authorized distributors of Ziggity products.

Ziggity Systems Offers Transparent Pipe Kit

Ziggity Systems Inc. has made it easy for poultry producers to find the support they need when installing Ziggity products or replacement parts on their poultry drinker lines.

The growing video series features short instructional videos such as:

- How to install Ace clip-on brackets

- How to install support pipe sections

- How to install clip-on saddles

- How to install floor Big Ace/Big Z clip-on brackets

- How to assemble T-Max drinkers

- How to install pipe connectors

- How to install the Ziggity Slope Neutralizer

- How to install and remove drinkers and avoid drinker damage

These installation videos can be found on the Ziggity website at Installation Videos

Ziggity Systems Releases Series of Installation VideosLink:

Assembly Instructions: 2628 – Big Ace X 3/4 MNPT OutletLink:

Assembly Instructions: 2629 – Ace X 3/4″ MNPT OutletT-Max Drinker Assembly Guideline

PS1002Performance results for adult turkeys (4 weeks to depletion) using Ziggity’s T-Max watering systems. Results confirm solid performance in areas of weight, feed conversion rates, livability and grade out with exceptional improvements in litter quality and ammonia reduction.

Adult Turkey Performance – Males/Toms – Various 2012 – 2013Solid results with dry litter.

Adult Turkey Performance – Females/Hens – 2014 Week 33Excessive iron can cause problems for watering systems. Article presents some ways to avoid that, including best practices for keeping watering systems clean.

Watch that IronOne of the most important and misunderstood jobs in a poultry house is managing the water pressure of the watering system. Here are ten tips for achieving optimal performance from a flock.

Ten tips to achieve optimal water pressureWith all the different drinkers on the market, it’s not surprising some producers get confused and choose the wrong drinker.

How to determine the right drinker for the jobProducers can achieve better turkey performance by making improvements in the birds’ immediate environment and the quality of water they drink.

Improve turkey performance by improving environment and water qualityMany times the roadblocks to better profits are misconceptions about watering

Five common poultry watering mythsGroundwater changes over time. Farmers need test for what’s in the water on a regular basis.

What’s in the water can impact commercial layer performancePoor conditions during brooding will damage a flocks’ performance.

Managing your watering system during broodingTo remain competitive, producers need to address aging equipment.

Upgrading for a successful poultry operationThe watering system, and how you manage it, can impact almost every aspect of a poultry operation.

Managing your watering system to promote poultry healthThe watering system has become the preferred method for administering live vaccines to broiler flocks because of the labor it saves.

Vaccinating broilers with the watering systemLink:

Assembly Instructions: 2790 – Pressure ProMost producers understand the importance of having a backup generator; however, some don’t realize they also need to back up the watering system

Protecting water supply crucial for any poultry operationPoultry equipment manufacturers seek innovations that can save producers time and money.

Watering system advances can save time and moneyGetting a poultry flock off to a healthy start goes a long way to ensuring a successful growout.

Treat chicks to a more hygienic environment for better resultsThe pressure on commercial egg producers to change from battery cages to an alternative form of housing requires them to rethink how they supply the birds with water.

Watering system for cage-free commercial layer operation needs special thoughtFor proper and complete installation of the Ziggity Pressure Pro for Floor Watering System please read and follow the illustrated instructions found in this manual.

Pressure Pro Installation ManualTo effectively manage your watering system, it’s important to understand how water usage involves both bird consumption and drinker spillage, and how these factors affect production. First in a series on watering system management concepts.

Usage = Consumption + Spillage, Article 1A number of factors can negatively impact return on investment, but corrosion is probably the most serious.

Corrosion poses a major threat to poultry operationsA lack of salt in the diet, or too much salt, can harm the flock and production.

Striking the right balance for salt intakeThe importance of managing the watering system to promote bird health is increasing with the growing opposition to using antibiotics as growth promoters.

Managing the watering system for intestinal integrityPoultry watering system components are primarily comprise of various types of plastic. The use of plastics in the watering systems has many advantages, including the abililty to withstsnd the corrosive atmosphere common to poultry operations.

Chemicals that can damage poulty watering systemsZiggity describes specific steps producers can take with their watering systems to improve return on investment.

Using your watering system to get better return on investmentParker-Hannifin Corp. recently developed the first water filter made specifically for poultry applications.

Poultry farmers gain new option for filtering waterThis article examines the very basics of how a nipple-type watering system, especially the regulator, works.

Understanding how a regulator functionsThis article discusses what elements of the watering system need examining and gives a time table for those examinations.

When was the last time you checked your watering system?Describes how to set up a watering system for a cage-free operation.

The watering system for a cage-free egg operationThis article provides the procedure to clean a watering system that has a sand problem.

Sand in your watering system: best to stop it at the sourceThe American poultry industry is finding a new profit center exporting chicken paws to China where they are considered a delicacy.

Making chicken paws profitableMajor US broiler integrator’s results in head to head comparison between Ziggity’s Aktive Max3 and Gold Drinker models. (moderate versus high dynamic flow drinkers) Superior litter and air quality made for a better environment – hence bird performance improves as well.

Broiler Performance USAHygienic water is vital in a successful poultry operation

Hygienic waterWill the gain in production outweigh the costs of replacing equipment damaged by acidifiers?

Use acids in poultry production with cautionAny biosecurity program that is truly successful will include extensive prophylactic measures involving the water supply and the watering system.

Don’t let your watering system become the fatal flaw in your biosecurity programZiggity has developed a series of protocols to help you determine the cause of your wet litter

How to combat wet litterThis article discusses tactics producers can take with their watering system to manage heat stress

Managing heat stress with your watering systemManaging your watering system to prevent wet litter can help keep the incidence of coccidiosis down

Fighting coccidiosisA simple and easy guide to ensure dry litter and ample water to your birds

Pressure Settings SimplifiedThis is a short summary of the basics of biofilm.

Biofilm BasicsMaintaining a good environment inside your poultry barn is necessary if you are to hae healthy and profitable flocks, growout after growout.

Water can be a friend or foe to a poultry operationPoultry producers can learn how to improve bird production through three educational brochures published by Ziggity Systems Inc.

New brochure series highlights ways to improve poultry performanceMore than a few experts in the poultry industry assume they can determine how much water a flock is consuming by looking at the water meter. That unfortunately is not true, and that assumption can lead to faulty practices.

Clearing the air: the difference between water usage and water consumptionFor proper and complete installation of the Ziggity Floor Watering System please read and follow the illustrated instructions found in this manual

Floor Watering Installation ManualFollow these simple instructions for proper installation of Ziggity Slope Neutralizers in floor applications.

Slope Neutralizer Floor Installation GuidelinesLink:

Assembly Instructions: 1293 – 1″ FNPT X MHT InletLink:

Assembly Instructions: 1494 – 1″ FNPT X 3/4″ MNPT InletLink:

Assembly Instructions: 1613 – Solenoid 1″ FNPT X MHT Inlet – 24 VACLink:

Assembly Instructions: 2674 – Solenoid 1″ FNPT X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 1291 – Big Ace X MHT InletLink:

Assembly Instructions: 1291B – Ace X MHT InletLink:

Assembly Instructions: 1491 – Big Ace X 3/4″ MNPT InletLink:

Assembly Instructions: 1491B – Ace X 3/4″ MNPT InletLink:

Assembly Instructions: 1611 – Solenoid Big Ace X MHT Inlet – 24 VACLink:

Assembly Instructions: 1611B – Solenoid Ace X MHT Inlet – 24 VACLink:

Assembly Instructions: 2673 – Solenoid Big Ace X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 2673B – Solenoid Ace X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 2948 – AT Big Ace X MHT InletLink:

Assembly Instructions: 2949 – AT Big Ace X 3/4″ MNPT InletLink:

Assembly Instructions: 2950 – Solenoid AT Big Ace X MHT Inlet – 24 VACLink:

Assembly Instructions: 2951 – Solenoid AT Big Ace X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 1807-6R – Big Ace 5.5″ / 14 CM Average Reduction – RightLink:

Assembly Instructions: 1807-6L- Big Ace 5.5″ / 14 CM Average Reduction – LeftLink:

Assembly Instructions: 1807B-6R – Ace 5.5″ / 14 CM Average Reduction – RightLink:

Assembly Instructions: 1807B-6L – Ace 5.5″ / 14 CM Average Reduction – LeftLink:

Assembly Instructions: 1958-6 – Big Ace 5.5″ / 14 CM Average Reduction – No Riser TubeLink:

Assembly Instructions: 1958B-6 Cage Slope Neutralizer Assembly InstructionsLink:

Assembly Instructions: 1958B-6 – Ace 5.5″ / 14 CM Average Reduction 3/4 No Riser TubeLink:

Assembly Instructions: 1920-4 – Big Ace 4.25″ / 10.8 CM Average ReductionLink:

Assembly Instructions: 1920B-4 – Ace 4.25″ / 10.8 CM Average ReductionLink:

Assembly Instructions: 3825 – Ace – Aluminium ProfileLink:

Assembly Instructions: 3826 – Big Ace – Aluminium ProfileLink:

Assembly Instructions: 3827 – Ace – Aluminium ProfileLink:

Assembly Instructions: 3828 – Big Ace – Aluminium ProfileLink:

Assembly Instructions: 2930 – Big Ace X MHT OutletLink:

Assembly Instructions: 2931 – Ace X MHT OutletLink:

Assembly Instructions: 2629 FLOOR END ASSEMBLY: ACE X 3/4 MNPT OUTLET Assembly InstructionsStrict adherence to good management practices throughout the poultry operation, especially the watering system, is the only way producers can reduce the impact of respiratory disease on their flocks and profit.

Managing poultry barn environment key to controlling respiratory diseaseMany producers are not aware of the important role the watering system has in the feed conversion process.

Managing your watering system to improve feed conversionHow proper watering system setup and management can overcome the challenges of sloped floors.

When you can’t be on the levelWatering System automation has enabled producers to reduce labor costs and improve productivity.

Automated watering systems improve layer producers’ bottom linesWhat is the best way to measure the effectiveness of your watering system? Dont be fooled by some common misunderstandings in this important area. This brochure helps you base your evaluation on the only thing that really matters performance.

Performance MattersCompatibility: Clip-On Brackets to Big Z and Clip-On Saddles

GL1007Compatibility: Clip-On Brackets to TL Saddle

GL1008Drinker Manufacturing Date Codes

GL1009Square Pipe to Big Ace & 1″ PVC Fittings

GL1017Solenoid Flush Valve Field Repair & Maintenance

GL1023Recommended Drain Hose Set Up Into Holding Tank

GL1027Filter Setup for Cage Operation

GL1030Non-Recommended Drain Hose Setup

GL1031Water Supply Setup: 3/4″

GL1033Water Supply Setup: 1″

GL1034Water Supply Setup: 1 1/2″

GL1035Actual Size: Ace, Big Ace & Big Z Pipes

GL1038Ziggity Aktive Drinker interface with Val nipple saddles

GL1043Recommended Spraying Procedures: TL Start Grow Systems

GL1045Warning: Never Use Pliers on Ziggity Drinkers

GL1052Installation: Preventing Support Pipe Separation

GL1055Field Fix: Riser Tube Cap

GL1056Installation: Cord Adjuster

GL1057Field Fix: Slope Neutralizer

GL1058Old Versus Current Aktive Drinkers: Visual Differences

GL1060Proper gaping instructions – Ziggity pipe connectors

GL1068Field Fix: loose floor end assemblies

GL1069Pipe Connector to Pipe Interface: 260, 896 & 2672

GL1070Water Capacity for Ziggity Drinker Pipes and Water Supply Pipes.

GL1074Installation Instructions: Clip-On Saddles

GL1079Installation Instructions: Bracket Placement for Floor Watering Systems

GL1080Installation Instructions: Regulator & End Assembly to Big Ace / Big Z / Ace Pipe

GL1081Regulator adjustment knob conversion to adult turkey regulator

GL1084O-Ring Guide for various Ziggity parts

GL1085Installation Instructions: Heavy Duty Anti-Roost Cable

GL1087Riser Tube Cap Alternative Assembly For Low Pressure Flushing (1 Bar / 15 PSI Or Less)

GL1089Installation Instructions: Clip-On Saddle Adapters

GL1090Note gain per day and feed conversion. Broiler performance that crosses State lines.

Georgia Results – 1We note a pattern here – do you?

Georgia Results – 2Ditto

Georgia Results – 3Japan Results – 1

Japan Results – 2

Japan Results – 3

Performance near the top.

Maryland Results – 1Roaster program results.

Maryland Results – 2More roaster program results.

Maryland Results – 3Last of three roaster program results.

Maryland Results – 4Still more roaster results – second location

Maryland Results – 5And still more roaster results.

Maryland Results – 6Broilers prefer sanitary water – they respond with better results

Max3 versus catch cup systemsThese broiler result truly cross state lines.

Mississippi Results -1Simply better in all categories and a day younger

Mississippi Results – 2Only 9 points better in FCR.

Mississippi Results – 3Even with slightly lower weights FCR’s were so much lower the grower ranked number one for the week!

Mississippi Results – 4Note the difference in daily weight gain.

Mississippi Results – 5More of the same in Mississippi!

Mississippi Results – 6Ditto

Mississippi Results – 7Go old Miss

Mississippi Results – 8We leave Mississippi on a high note!

Mississippi Results – 9Note better performance in every category.

More Max3 versus catch cup systemsFour identical houses. Two with Ziggity Max3 and two with Ziggity Gold drinkers. (Moderate versus high dynamic flow drinkers) Production cycle nr.1

North Carolina Field Test – Max3 versus Gold 1/4Second out of four consecutive broiler production cycles.

North Carolina Field Test – Max3 versus Gold 2/4Third our of 4 consecutive broiler production cycles.

North Carolina Field Test – Max3 versus Gold 3/4The final comparative performance results.

North Carolina Field Test – Max3 versus Gold 4/4Note the difference in feed conversion rate.

North Carolina Results -1Bigger birds and a much lower feed conversion rate compared against all birds processed that same week.

North Carolina Results – 2Again bigger birds and lower feed conversion rate.

North Carolina Results – 3Broiler performance comparison against the average for the week and previous 5 growouts with older high flow Ziggity drinkers.

North Carolina Results – 4Note weight gain per day and FCR.

North Carolina Results – 5Two days younger yet heavier and with a better feed conversion rate of only 12 points better.

North Carolina Results – 6More of the same from the great State of North Carolina.

North Carolina Results – 7Solid Performance!

Northeastern Results – 1Again!

Northeastern Results – 2Solid results!

Texas Results – 1More results for the state of Texas

Texas Results – 2Younger birds yet heavier and with a lower FCR – go figure!

Texas Results – 3And always that improvement in FCR.

Texas Results – 4First of four consecutive growouts on a heavy bird program.

USA Heavy Broiler Producer 1/4Second of four growouts. The numbers speak for themselves.

USA Heavy Broiler Producer 2/4More of the same!

USA Heavy Broiler Producer 3/4Last but certainly not least!

USA Heavy Broiler Producer 4/4It is almost impossible to overemphasize the importance of water to poultry flocks

The role of water in the life of a chickenProduct bundling may provide producers with a one-time savings when building a new poultry house. However, that bundle of products may result in loses over the long term.

Product bundling not in producers’ best interestsZiggity is the only company whose sole focus is on poultry watering.

Ziggity focuses on maximizing system, litter and bird performanceElevated levels of ammonia in the poultry house can result in a wide range of problems for poultry producers

Ammonia in the poultry house sabotages production; can impact poultry workers’ healthBiofilm is an often overlooked and misunderstood threat to poultry flocks

Poultry farmers often overlook biofilm growing in watering systemThe better you understand how and why birds drink water, the better you can provide for their needs and produce more profitable flocks.

Understand broiler drinking behavior to achieve better flock performanceFive ways to maximize the benefits of an enclosed watering system.

Maximizing the benefits of enclosed watering systemsGrowing a successful and profitable broiler flock requires diligent planning and management especially in preventing diseases and other conditions that harm the birds.

Planning necessary to prevent disease in poultry flockGravity-controlled water tanks provide an excellent solution to the challenges of unreliable electric power and intermittent water supply

Solutions to the five most common challenges found in gravity-controlled water tanksWater quality from wells plays an important role in flock performance.

Ignore your well at your own riskThe route to improving flock performance lies in good litter management.

Good litter management ensures flock performanceCommon mistakes producers make concerning their watering systems.

Five watering mistakes that can hurt productionThe watering system and how the farmer manages it determine many of the conditions in a parent stock operation.

Watering system critical in parent stock operationReturn on investment, not the up-front cost of a new barn, is the most important aspect to consider when building a new facility

Quality components, not special prices, required when building a new poultry barnMany of the decisions a poultry farmer is asked to make can carry unintended consequences that can hurt the bottom line

It may sound like a good idea, but is it really?EuroTier 2024

Hanover, Germany

November 12 – 15

Tool: Pipe Gap – Floor System Applications

GL1091Drinker Tool Guide

GL1092Field Fix: Inline Riser Assembly Sag

GL1093Ziggity Systems – André van Rij – Account Manager – Press Release

EMEA Account Manager Appointed by Ziggity Systems and Butterfly Concepts

— Ziggity Systems Inc., the maker of Ziggity brand poultry watering systems has developed helpful guidelines to help poultry producers with many common questions and needs regarding its watering systems. These guidelines are available on the company’s website, Ziggity.com.

To access these guidelines, which are designed to assist with best practices in product installation and usage, simply access the Ziggity website and find the “Guidelines” under the “Support” tab.

Guidelines available are subdivided under the headings, Field Fixes, Maintenance, Product Information, Product Installation and Warnings. Examples of guideline subjects are drinker manufacturing date codes, installation of heavy duty anti-roost cable and cord adjusters just to name a few.

“We want to make sure that our customers have ready access to important information that helps make them more efficient and successful,” said the company.

Another source of helpful information designed to help poultry producers maximize their performance can be found at the Poultry Watering U website. To visit Poultry Watering U click here.

Ziggity Systems Offers Helpful Online Guideline References

Ziggity Systems, Inc., the maker of Ziggity Brand poultry watering systems has added a library of helpful support videos for poultry producers on the company’s website, Ziggity.com. The growing video library is one element in Ziggity’s ongoing effort to help poultry producers maximize the benefits of their watering systems.

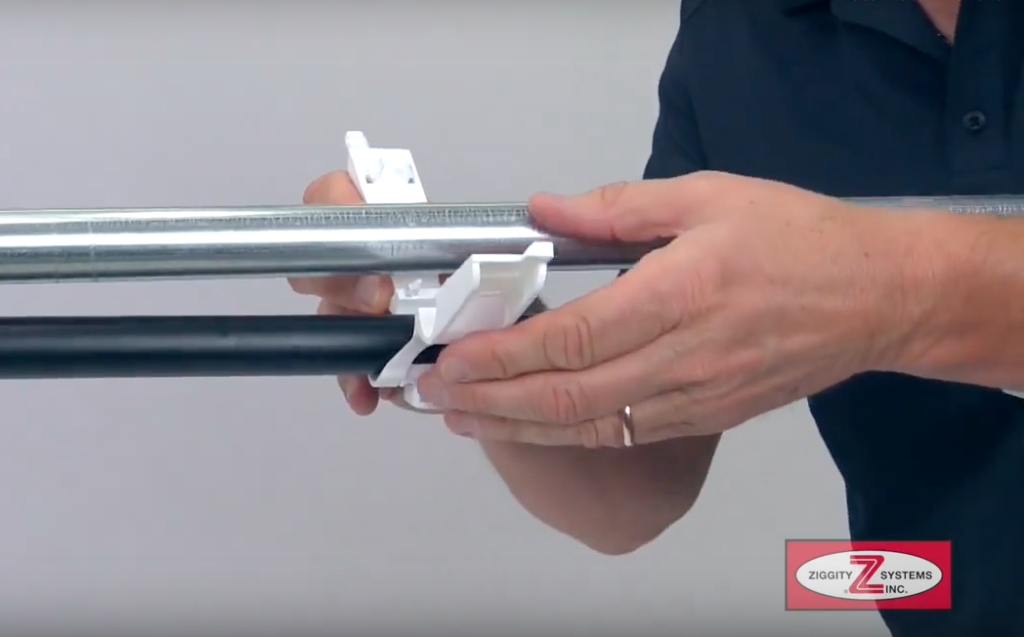

Two videos offer installation demonstrations for Clip-On brackets that are used to affix the water bearing pipe to the support pipe. One video shows installation of Clip-On brackets for Ace sized pipe while another video provides similar instructions for Big Ace/Big Z Clip-On brackets.

To view these videos and more, visit: https://ziggity.com/installation-videos/.

Another source of helpful information designed to help poultry producers maximize their performance can be found at the Poultry Watering U website at poultrywateringu.com.

Ziggity Systems Provides Support Videos for Clip-On Brackets

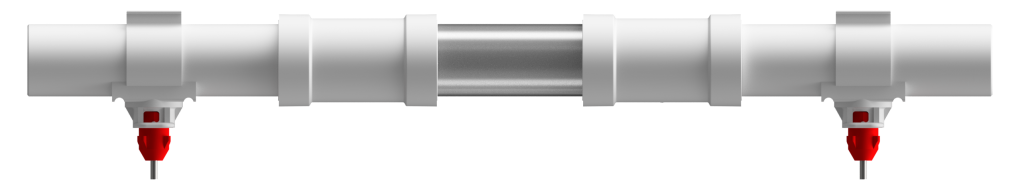

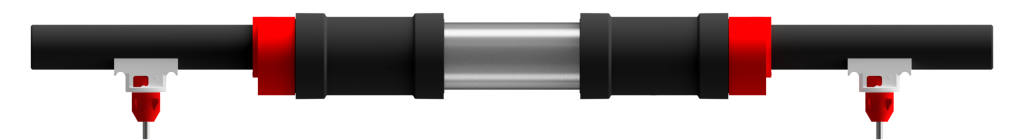

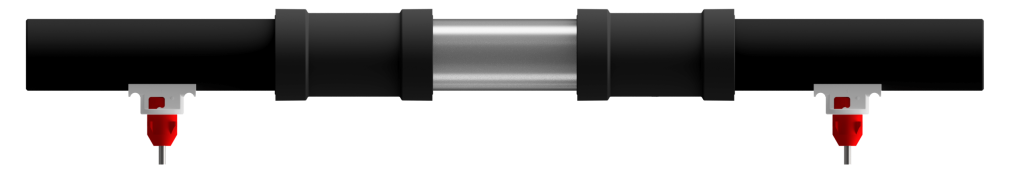

PN 4198 (for 1″ PVC pipe systems)

PN 4196 (for Ace pipe systems)

PN 4197 (for Big Ace pipe systems)

Ziggity Systems Inc. has made it easy for poultry producers to monitor and improve the quality of the water in their drinker lines with the transparent pipe kit. The kit is easily retrofitted onto existing Ziggity drinker lines. Once installed, water in the drinker lines can be visually monitored for contaminants such as biofilm, sediment and trapped air.

Ziggity Systems transparent pipe kit is an early warning indicator for: poor sanitation/biofilm, poor water filtration, trapped air, interventions that were not evenly dispersed or dissolved.

With the transparent pipe kit, debris getting past an ineffective filter can be observed, alerting producers to inspect the filtration system. During the production cycle when interventions are required, the transparent pipe kit allows for visual inspection inside the drinker line to confirm that the intervening materials are fully dissolved and evenly dispersed – which allows the producer to correct problems and improve the efficacy of the intervention.

The simple, easy-to-use water management tool is unique to Ziggity Systems and is compatible with any Ziggity Ace, Big Ace, Big Z or 1” PVC pipe system for all bird species and all bird applications – including floor and cage watering systems.

“A watering system is a key investment, and we urge producers to make use of this resource to be sure that investment is operating correctly for maximum performance,” according to the Ziggity technical team.

The transparent pipe kit can be installed directly out of the Ziggity regulator, directly into the Ziggity end assembly or any other location on the drinker line. They are available through authorized distributors of Ziggity products.

Ziggity Systems Offers Transparent Pipe Kit

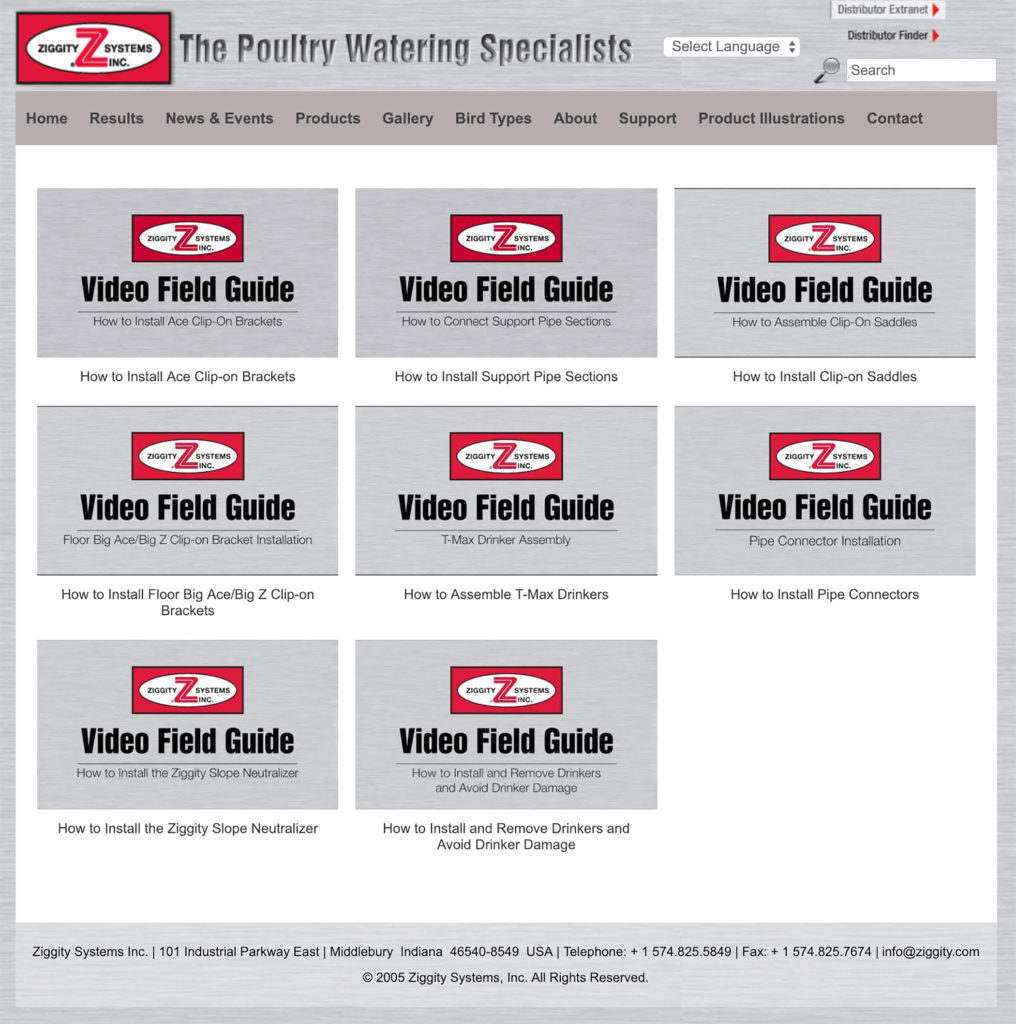

Ziggity Systems Inc. has made it easy for poultry producers to find the support they need when installing Ziggity products or replacement parts on their poultry drinker lines.

The growing video series features short instructional videos such as:

- How to install Ace clip-on brackets

- How to install support pipe sections

- How to install clip-on saddles

- How to install floor Big Ace/Big Z clip-on brackets

- How to assemble T-Max drinkers

- How to install pipe connectors

- How to install the Ziggity Slope Neutralizer

- How to install and remove drinkers and avoid drinker damage

These installation videos can be found on the Ziggity website at Installation Videos

Ziggity Systems Releases Series of Installation VideosLink:

Assembly Instructions: 2628 – Big Ace X 3/4 MNPT OutletLink:

Assembly Instructions: 2629 – Ace X 3/4″ MNPT OutletT-Max Drinker Assembly Guideline

PS1002Performance results for adult turkeys (4 weeks to depletion) using Ziggity’s T-Max watering systems. Results confirm solid performance in areas of weight, feed conversion rates, livability and grade out with exceptional improvements in litter quality and ammonia reduction.

Adult Turkey Performance – Males/Toms – Various 2012 – 2013Solid results with dry litter.

Adult Turkey Performance – Females/Hens – 2014 Week 33Excessive iron can cause problems for watering systems. Article presents some ways to avoid that, including best practices for keeping watering systems clean.

Watch that IronOne of the most important and misunderstood jobs in a poultry house is managing the water pressure of the watering system. Here are ten tips for achieving optimal performance from a flock.

Ten tips to achieve optimal water pressureWith all the different drinkers on the market, it’s not surprising some producers get confused and choose the wrong drinker.

How to determine the right drinker for the jobProducers can achieve better turkey performance by making improvements in the birds’ immediate environment and the quality of water they drink.

Improve turkey performance by improving environment and water qualityMany times the roadblocks to better profits are misconceptions about watering

Five common poultry watering mythsGroundwater changes over time. Farmers need test for what’s in the water on a regular basis.

What’s in the water can impact commercial layer performancePoor conditions during brooding will damage a flocks’ performance.

Managing your watering system during broodingTo remain competitive, producers need to address aging equipment.

Upgrading for a successful poultry operationThe watering system, and how you manage it, can impact almost every aspect of a poultry operation.

Managing your watering system to promote poultry healthThe watering system has become the preferred method for administering live vaccines to broiler flocks because of the labor it saves.

Vaccinating broilers with the watering systemLink:

Assembly Instructions: 2790 – Pressure ProMost producers understand the importance of having a backup generator; however, some don’t realize they also need to back up the watering system

Protecting water supply crucial for any poultry operationPoultry equipment manufacturers seek innovations that can save producers time and money.

Watering system advances can save time and moneyGetting a poultry flock off to a healthy start goes a long way to ensuring a successful growout.

Treat chicks to a more hygienic environment for better resultsThe pressure on commercial egg producers to change from battery cages to an alternative form of housing requires them to rethink how they supply the birds with water.

Watering system for cage-free commercial layer operation needs special thoughtFor proper and complete installation of the Ziggity Pressure Pro for Floor Watering System please read and follow the illustrated instructions found in this manual.

Pressure Pro Installation ManualTo effectively manage your watering system, it’s important to understand how water usage involves both bird consumption and drinker spillage, and how these factors affect production. First in a series on watering system management concepts.

Usage = Consumption + Spillage, Article 1A number of factors can negatively impact return on investment, but corrosion is probably the most serious.

Corrosion poses a major threat to poultry operationsA lack of salt in the diet, or too much salt, can harm the flock and production.

Striking the right balance for salt intakeThe importance of managing the watering system to promote bird health is increasing with the growing opposition to using antibiotics as growth promoters.

Managing the watering system for intestinal integrityPoultry watering system components are primarily comprise of various types of plastic. The use of plastics in the watering systems has many advantages, including the abililty to withstsnd the corrosive atmosphere common to poultry operations.

Chemicals that can damage poulty watering systemsZiggity describes specific steps producers can take with their watering systems to improve return on investment.

Using your watering system to get better return on investmentParker-Hannifin Corp. recently developed the first water filter made specifically for poultry applications.

Poultry farmers gain new option for filtering waterThis article examines the very basics of how a nipple-type watering system, especially the regulator, works.

Understanding how a regulator functionsThis article discusses what elements of the watering system need examining and gives a time table for those examinations.

When was the last time you checked your watering system?Describes how to set up a watering system for a cage-free operation.

The watering system for a cage-free egg operationThis article provides the procedure to clean a watering system that has a sand problem.

Sand in your watering system: best to stop it at the sourceThe American poultry industry is finding a new profit center exporting chicken paws to China where they are considered a delicacy.

Making chicken paws profitableMajor US broiler integrator’s results in head to head comparison between Ziggity’s Aktive Max3 and Gold Drinker models. (moderate versus high dynamic flow drinkers) Superior litter and air quality made for a better environment – hence bird performance improves as well.

Broiler Performance USAHygienic water is vital in a successful poultry operation

Hygienic waterWill the gain in production outweigh the costs of replacing equipment damaged by acidifiers?

Use acids in poultry production with cautionAny biosecurity program that is truly successful will include extensive prophylactic measures involving the water supply and the watering system.

Don’t let your watering system become the fatal flaw in your biosecurity programZiggity has developed a series of protocols to help you determine the cause of your wet litter

How to combat wet litterThis article discusses tactics producers can take with their watering system to manage heat stress

Managing heat stress with your watering systemManaging your watering system to prevent wet litter can help keep the incidence of coccidiosis down

Fighting coccidiosisA simple and easy guide to ensure dry litter and ample water to your birds

Pressure Settings SimplifiedThis is a short summary of the basics of biofilm.

Biofilm BasicsMaintaining a good environment inside your poultry barn is necessary if you are to hae healthy and profitable flocks, growout after growout.

Water can be a friend or foe to a poultry operationPoultry producers can learn how to improve bird production through three educational brochures published by Ziggity Systems Inc.

New brochure series highlights ways to improve poultry performanceMore than a few experts in the poultry industry assume they can determine how much water a flock is consuming by looking at the water meter. That unfortunately is not true, and that assumption can lead to faulty practices.

Clearing the air: the difference between water usage and water consumptionFor proper and complete installation of the Ziggity Floor Watering System please read and follow the illustrated instructions found in this manual

Floor Watering Installation ManualFollow these simple instructions for proper installation of Ziggity Slope Neutralizers in floor applications.

Slope Neutralizer Floor Installation GuidelinesLink:

Assembly Instructions: 1293 – 1″ FNPT X MHT InletLink:

Assembly Instructions: 1494 – 1″ FNPT X 3/4″ MNPT InletLink:

Assembly Instructions: 1613 – Solenoid 1″ FNPT X MHT Inlet – 24 VACLink:

Assembly Instructions: 2674 – Solenoid 1″ FNPT X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 1291 – Big Ace X MHT InletLink:

Assembly Instructions: 1291B – Ace X MHT InletLink:

Assembly Instructions: 1491 – Big Ace X 3/4″ MNPT InletLink:

Assembly Instructions: 1491B – Ace X 3/4″ MNPT InletLink:

Assembly Instructions: 1611 – Solenoid Big Ace X MHT Inlet – 24 VACLink:

Assembly Instructions: 1611B – Solenoid Ace X MHT Inlet – 24 VACLink:

Assembly Instructions: 2673 – Solenoid Big Ace X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 2673B – Solenoid Ace X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 2948 – AT Big Ace X MHT InletLink:

Assembly Instructions: 2949 – AT Big Ace X 3/4″ MNPT InletLink:

Assembly Instructions: 2950 – Solenoid AT Big Ace X MHT Inlet – 24 VACLink:

Assembly Instructions: 2951 – Solenoid AT Big Ace X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 1807-6R – Big Ace 5.5″ / 14 CM Average Reduction – RightLink:

Assembly Instructions: 1807-6L- Big Ace 5.5″ / 14 CM Average Reduction – LeftLink:

Assembly Instructions: 1807B-6R – Ace 5.5″ / 14 CM Average Reduction – RightLink:

Assembly Instructions: 1807B-6L – Ace 5.5″ / 14 CM Average Reduction – LeftLink:

Assembly Instructions: 1958-6 – Big Ace 5.5″ / 14 CM Average Reduction – No Riser TubeLink:

Assembly Instructions: 1958B-6 Cage Slope Neutralizer Assembly InstructionsLink:

Assembly Instructions: 1958B-6 – Ace 5.5″ / 14 CM Average Reduction 3/4 No Riser TubeLink:

Assembly Instructions: 1920-4 – Big Ace 4.25″ / 10.8 CM Average ReductionLink:

Assembly Instructions: 1920B-4 – Ace 4.25″ / 10.8 CM Average ReductionLink:

Assembly Instructions: 3825 – Ace – Aluminium ProfileLink:

Assembly Instructions: 3826 – Big Ace – Aluminium ProfileLink:

Assembly Instructions: 3827 – Ace – Aluminium ProfileLink:

Assembly Instructions: 3828 – Big Ace – Aluminium ProfileLink:

Assembly Instructions: 2930 – Big Ace X MHT OutletLink:

Assembly Instructions: 2931 – Ace X MHT OutletLink:

Assembly Instructions: 2629 FLOOR END ASSEMBLY: ACE X 3/4 MNPT OUTLET Assembly InstructionsStrict adherence to good management practices throughout the poultry operation, especially the watering system, is the only way producers can reduce the impact of respiratory disease on their flocks and profit.

Managing poultry barn environment key to controlling respiratory diseaseMany producers are not aware of the important role the watering system has in the feed conversion process.

Managing your watering system to improve feed conversionHow proper watering system setup and management can overcome the challenges of sloped floors.

When you can’t be on the levelWatering System automation has enabled producers to reduce labor costs and improve productivity.

Automated watering systems improve layer producers’ bottom linesWhat is the best way to measure the effectiveness of your watering system? Dont be fooled by some common misunderstandings in this important area. This brochure helps you base your evaluation on the only thing that really matters performance.

Performance MattersCompatibility: Clip-On Brackets to Big Z and Clip-On Saddles

GL1007Compatibility: Clip-On Brackets to TL Saddle

GL1008Drinker Manufacturing Date Codes

GL1009Square Pipe to Big Ace & 1″ PVC Fittings

GL1017Solenoid Flush Valve Field Repair & Maintenance

GL1023Recommended Drain Hose Set Up Into Holding Tank

GL1027Filter Setup for Cage Operation

GL1030Non-Recommended Drain Hose Setup

GL1031Water Supply Setup: 3/4″

GL1033Water Supply Setup: 1″

GL1034Water Supply Setup: 1 1/2″

GL1035Actual Size: Ace, Big Ace & Big Z Pipes

GL1038Ziggity Aktive Drinker interface with Val nipple saddles

GL1043Recommended Spraying Procedures: TL Start Grow Systems

GL1045Warning: Never Use Pliers on Ziggity Drinkers

GL1052Installation: Preventing Support Pipe Separation

GL1055Field Fix: Riser Tube Cap

GL1056Installation: Cord Adjuster

GL1057Field Fix: Slope Neutralizer

GL1058Old Versus Current Aktive Drinkers: Visual Differences

GL1060Proper gaping instructions – Ziggity pipe connectors

GL1068Field Fix: loose floor end assemblies

GL1069Pipe Connector to Pipe Interface: 260, 896 & 2672

GL1070Water Capacity for Ziggity Drinker Pipes and Water Supply Pipes.

GL1074Installation Instructions: Clip-On Saddles

GL1079Installation Instructions: Bracket Placement for Floor Watering Systems

GL1080Installation Instructions: Regulator & End Assembly to Big Ace / Big Z / Ace Pipe

GL1081Regulator adjustment knob conversion to adult turkey regulator

GL1084O-Ring Guide for various Ziggity parts

GL1085Installation Instructions: Heavy Duty Anti-Roost Cable

GL1087Riser Tube Cap Alternative Assembly For Low Pressure Flushing (1 Bar / 15 PSI Or Less)

GL1089Installation Instructions: Clip-On Saddle Adapters

GL1090Note gain per day and feed conversion. Broiler performance that crosses State lines.

Georgia Results – 1We note a pattern here – do you?

Georgia Results – 2Ditto

Georgia Results – 3Japan Results – 1

Japan Results – 2

Japan Results – 3

Performance near the top.

Maryland Results – 1Roaster program results.

Maryland Results – 2More roaster program results.

Maryland Results – 3Last of three roaster program results.

Maryland Results – 4Still more roaster results – second location

Maryland Results – 5And still more roaster results.

Maryland Results – 6Broilers prefer sanitary water – they respond with better results

Max3 versus catch cup systemsThese broiler result truly cross state lines.

Mississippi Results -1Simply better in all categories and a day younger

Mississippi Results – 2Only 9 points better in FCR.

Mississippi Results – 3Even with slightly lower weights FCR’s were so much lower the grower ranked number one for the week!

Mississippi Results – 4Note the difference in daily weight gain.

Mississippi Results – 5More of the same in Mississippi!

Mississippi Results – 6Ditto

Mississippi Results – 7Go old Miss

Mississippi Results – 8We leave Mississippi on a high note!

Mississippi Results – 9Note better performance in every category.

More Max3 versus catch cup systemsFour identical houses. Two with Ziggity Max3 and two with Ziggity Gold drinkers. (Moderate versus high dynamic flow drinkers) Production cycle nr.1

North Carolina Field Test – Max3 versus Gold 1/4Second out of four consecutive broiler production cycles.

North Carolina Field Test – Max3 versus Gold 2/4Third our of 4 consecutive broiler production cycles.

North Carolina Field Test – Max3 versus Gold 3/4The final comparative performance results.

North Carolina Field Test – Max3 versus Gold 4/4Note the difference in feed conversion rate.

North Carolina Results -1Bigger birds and a much lower feed conversion rate compared against all birds processed that same week.

North Carolina Results – 2Again bigger birds and lower feed conversion rate.

North Carolina Results – 3Broiler performance comparison against the average for the week and previous 5 growouts with older high flow Ziggity drinkers.

North Carolina Results – 4Note weight gain per day and FCR.

North Carolina Results – 5Two days younger yet heavier and with a better feed conversion rate of only 12 points better.

North Carolina Results – 6More of the same from the great State of North Carolina.

North Carolina Results – 7Solid Performance!

Northeastern Results – 1Again!

Northeastern Results – 2Solid results!

Texas Results – 1More results for the state of Texas

Texas Results – 2Younger birds yet heavier and with a lower FCR – go figure!

Texas Results – 3And always that improvement in FCR.

Texas Results – 4First of four consecutive growouts on a heavy bird program.

USA Heavy Broiler Producer 1/4Second of four growouts. The numbers speak for themselves.

USA Heavy Broiler Producer 2/4More of the same!

USA Heavy Broiler Producer 3/4Last but certainly not least!

USA Heavy Broiler Producer 4/4It is almost impossible to overemphasize the importance of water to poultry flocks

The role of water in the life of a chickenProduct bundling may provide producers with a one-time savings when building a new poultry house. However, that bundle of products may result in loses over the long term.

Product bundling not in producers’ best interestsZiggity is the only company whose sole focus is on poultry watering.

Ziggity focuses on maximizing system, litter and bird performanceElevated levels of ammonia in the poultry house can result in a wide range of problems for poultry producers

Ammonia in the poultry house sabotages production; can impact poultry workers’ healthBiofilm is an often overlooked and misunderstood threat to poultry flocks

Poultry farmers often overlook biofilm growing in watering systemThe better you understand how and why birds drink water, the better you can provide for their needs and produce more profitable flocks.

Understand broiler drinking behavior to achieve better flock performanceFive ways to maximize the benefits of an enclosed watering system.

Maximizing the benefits of enclosed watering systemsGrowing a successful and profitable broiler flock requires diligent planning and management especially in preventing diseases and other conditions that harm the birds.

Planning necessary to prevent disease in poultry flockGravity-controlled water tanks provide an excellent solution to the challenges of unreliable electric power and intermittent water supply

Solutions to the five most common challenges found in gravity-controlled water tanksWater quality from wells plays an important role in flock performance.

Ignore your well at your own riskThe route to improving flock performance lies in good litter management.

Good litter management ensures flock performanceCommon mistakes producers make concerning their watering systems.

Five watering mistakes that can hurt productionThe watering system and how the farmer manages it determine many of the conditions in a parent stock operation.

Watering system critical in parent stock operationReturn on investment, not the up-front cost of a new barn, is the most important aspect to consider when building a new facility

Quality components, not special prices, required when building a new poultry barnMany of the decisions a poultry farmer is asked to make can carry unintended consequences that can hurt the bottom line

It may sound like a good idea, but is it really?Management Procedures (PDF):

EuroTier 2024

Hanover, Germany

November 12 – 15

Tool: Pipe Gap – Floor System Applications

GL1091Drinker Tool Guide

GL1092Field Fix: Inline Riser Assembly Sag

GL1093Ziggity Systems – André van Rij – Account Manager – Press Release

EMEA Account Manager Appointed by Ziggity Systems and Butterfly Concepts

— Ziggity Systems Inc., the maker of Ziggity brand poultry watering systems has developed helpful guidelines to help poultry producers with many common questions and needs regarding its watering systems. These guidelines are available on the company’s website, Ziggity.com.

To access these guidelines, which are designed to assist with best practices in product installation and usage, simply access the Ziggity website and find the “Guidelines” under the “Support” tab.

Guidelines available are subdivided under the headings, Field Fixes, Maintenance, Product Information, Product Installation and Warnings. Examples of guideline subjects are drinker manufacturing date codes, installation of heavy duty anti-roost cable and cord adjusters just to name a few.

“We want to make sure that our customers have ready access to important information that helps make them more efficient and successful,” said the company.

Another source of helpful information designed to help poultry producers maximize their performance can be found at the Poultry Watering U website. To visit Poultry Watering U click here.

Ziggity Systems Offers Helpful Online Guideline References

Ziggity Systems, Inc., the maker of Ziggity Brand poultry watering systems has added a library of helpful support videos for poultry producers on the company’s website, Ziggity.com. The growing video library is one element in Ziggity’s ongoing effort to help poultry producers maximize the benefits of their watering systems.

Two videos offer installation demonstrations for Clip-On brackets that are used to affix the water bearing pipe to the support pipe. One video shows installation of Clip-On brackets for Ace sized pipe while another video provides similar instructions for Big Ace/Big Z Clip-On brackets.

To view these videos and more, visit: https://ziggity.com/installation-videos/.

Another source of helpful information designed to help poultry producers maximize their performance can be found at the Poultry Watering U website at poultrywateringu.com.

Ziggity Systems Provides Support Videos for Clip-On Brackets

PN 4198 (for 1″ PVC pipe systems)

PN 4196 (for Ace pipe systems)

PN 4197 (for Big Ace pipe systems)

Ziggity Systems Inc. has made it easy for poultry producers to monitor and improve the quality of the water in their drinker lines with the transparent pipe kit. The kit is easily retrofitted onto existing Ziggity drinker lines. Once installed, water in the drinker lines can be visually monitored for contaminants such as biofilm, sediment and trapped air.

Ziggity Systems transparent pipe kit is an early warning indicator for: poor sanitation/biofilm, poor water filtration, trapped air, interventions that were not evenly dispersed or dissolved.

With the transparent pipe kit, debris getting past an ineffective filter can be observed, alerting producers to inspect the filtration system. During the production cycle when interventions are required, the transparent pipe kit allows for visual inspection inside the drinker line to confirm that the intervening materials are fully dissolved and evenly dispersed – which allows the producer to correct problems and improve the efficacy of the intervention.

The simple, easy-to-use water management tool is unique to Ziggity Systems and is compatible with any Ziggity Ace, Big Ace, Big Z or 1” PVC pipe system for all bird species and all bird applications – including floor and cage watering systems.

“A watering system is a key investment, and we urge producers to make use of this resource to be sure that investment is operating correctly for maximum performance,” according to the Ziggity technical team.

The transparent pipe kit can be installed directly out of the Ziggity regulator, directly into the Ziggity end assembly or any other location on the drinker line. They are available through authorized distributors of Ziggity products.

Ziggity Systems Offers Transparent Pipe Kit

Ziggity Systems Inc. has made it easy for poultry producers to find the support they need when installing Ziggity products or replacement parts on their poultry drinker lines.

The growing video series features short instructional videos such as:

- How to install Ace clip-on brackets

- How to install support pipe sections

- How to install clip-on saddles

- How to install floor Big Ace/Big Z clip-on brackets

- How to assemble T-Max drinkers

- How to install pipe connectors

- How to install the Ziggity Slope Neutralizer

- How to install and remove drinkers and avoid drinker damage

These installation videos can be found on the Ziggity website at Installation Videos

Ziggity Systems Releases Series of Installation VideosLink:

Assembly Instructions: 2628 – Big Ace X 3/4 MNPT OutletLink:

Assembly Instructions: 2629 – Ace X 3/4″ MNPT OutletT-Max Drinker Assembly Guideline

PS1002Performance results for adult turkeys (4 weeks to depletion) using Ziggity’s T-Max watering systems. Results confirm solid performance in areas of weight, feed conversion rates, livability and grade out with exceptional improvements in litter quality and ammonia reduction.

Adult Turkey Performance – Males/Toms – Various 2012 – 2013Solid results with dry litter.

Adult Turkey Performance – Females/Hens – 2014 Week 33Excessive iron can cause problems for watering systems. Article presents some ways to avoid that, including best practices for keeping watering systems clean.

Watch that IronOne of the most important and misunderstood jobs in a poultry house is managing the water pressure of the watering system. Here are ten tips for achieving optimal performance from a flock.

Ten tips to achieve optimal water pressureWith all the different drinkers on the market, it’s not surprising some producers get confused and choose the wrong drinker.

How to determine the right drinker for the jobProducers can achieve better turkey performance by making improvements in the birds’ immediate environment and the quality of water they drink.

Improve turkey performance by improving environment and water qualityMany times the roadblocks to better profits are misconceptions about watering

Five common poultry watering mythsGroundwater changes over time. Farmers need test for what’s in the water on a regular basis.

What’s in the water can impact commercial layer performancePoor conditions during brooding will damage a flocks’ performance.

Managing your watering system during broodingTo remain competitive, producers need to address aging equipment.

Upgrading for a successful poultry operationThe watering system, and how you manage it, can impact almost every aspect of a poultry operation.

Managing your watering system to promote poultry healthThe watering system has become the preferred method for administering live vaccines to broiler flocks because of the labor it saves.

Vaccinating broilers with the watering systemLink:

Assembly Instructions: 2790 – Pressure ProMost producers understand the importance of having a backup generator; however, some don’t realize they also need to back up the watering system

Protecting water supply crucial for any poultry operationPoultry equipment manufacturers seek innovations that can save producers time and money.

Watering system advances can save time and moneyGetting a poultry flock off to a healthy start goes a long way to ensuring a successful growout.

Treat chicks to a more hygienic environment for better resultsThe pressure on commercial egg producers to change from battery cages to an alternative form of housing requires them to rethink how they supply the birds with water.

Watering system for cage-free commercial layer operation needs special thoughtFor proper and complete installation of the Ziggity Pressure Pro for Floor Watering System please read and follow the illustrated instructions found in this manual.

Pressure Pro Installation ManualTo effectively manage your watering system, it’s important to understand how water usage involves both bird consumption and drinker spillage, and how these factors affect production. First in a series on watering system management concepts.

Usage = Consumption + Spillage, Article 1A number of factors can negatively impact return on investment, but corrosion is probably the most serious.

Corrosion poses a major threat to poultry operationsA lack of salt in the diet, or too much salt, can harm the flock and production.

Striking the right balance for salt intakeThe importance of managing the watering system to promote bird health is increasing with the growing opposition to using antibiotics as growth promoters.

Managing the watering system for intestinal integrityPoultry watering system components are primarily comprise of various types of plastic. The use of plastics in the watering systems has many advantages, including the abililty to withstsnd the corrosive atmosphere common to poultry operations.

Chemicals that can damage poulty watering systemsZiggity describes specific steps producers can take with their watering systems to improve return on investment.

Using your watering system to get better return on investmentParker-Hannifin Corp. recently developed the first water filter made specifically for poultry applications.

Poultry farmers gain new option for filtering waterThis article examines the very basics of how a nipple-type watering system, especially the regulator, works.

Understanding how a regulator functionsThis article discusses what elements of the watering system need examining and gives a time table for those examinations.

When was the last time you checked your watering system?Describes how to set up a watering system for a cage-free operation.

The watering system for a cage-free egg operationThis article provides the procedure to clean a watering system that has a sand problem.

Sand in your watering system: best to stop it at the sourceThe American poultry industry is finding a new profit center exporting chicken paws to China where they are considered a delicacy.

Making chicken paws profitableMajor US broiler integrator’s results in head to head comparison between Ziggity’s Aktive Max3 and Gold Drinker models. (moderate versus high dynamic flow drinkers) Superior litter and air quality made for a better environment – hence bird performance improves as well.

Broiler Performance USAHygienic water is vital in a successful poultry operation

Hygienic waterWill the gain in production outweigh the costs of replacing equipment damaged by acidifiers?

Use acids in poultry production with cautionAny biosecurity program that is truly successful will include extensive prophylactic measures involving the water supply and the watering system.

Don’t let your watering system become the fatal flaw in your biosecurity programZiggity has developed a series of protocols to help you determine the cause of your wet litter

How to combat wet litterThis article discusses tactics producers can take with their watering system to manage heat stress

Managing heat stress with your watering systemManaging your watering system to prevent wet litter can help keep the incidence of coccidiosis down

Fighting coccidiosisA simple and easy guide to ensure dry litter and ample water to your birds

Pressure Settings SimplifiedThis is a short summary of the basics of biofilm.

Biofilm BasicsMaintaining a good environment inside your poultry barn is necessary if you are to hae healthy and profitable flocks, growout after growout.

Water can be a friend or foe to a poultry operationPoultry producers can learn how to improve bird production through three educational brochures published by Ziggity Systems Inc.

New brochure series highlights ways to improve poultry performanceMore than a few experts in the poultry industry assume they can determine how much water a flock is consuming by looking at the water meter. That unfortunately is not true, and that assumption can lead to faulty practices.

Clearing the air: the difference between water usage and water consumptionFor proper and complete installation of the Ziggity Floor Watering System please read and follow the illustrated instructions found in this manual

Floor Watering Installation ManualFollow these simple instructions for proper installation of Ziggity Slope Neutralizers in floor applications.

Slope Neutralizer Floor Installation GuidelinesLink:

Assembly Instructions: 1293 – 1″ FNPT X MHT InletLink:

Assembly Instructions: 1494 – 1″ FNPT X 3/4″ MNPT InletLink:

Assembly Instructions: 1613 – Solenoid 1″ FNPT X MHT Inlet – 24 VACLink:

Assembly Instructions: 2674 – Solenoid 1″ FNPT X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 1291 – Big Ace X MHT InletLink:

Assembly Instructions: 1291B – Ace X MHT InletLink:

Assembly Instructions: 1491 – Big Ace X 3/4″ MNPT InletLink:

Assembly Instructions: 1491B – Ace X 3/4″ MNPT InletLink:

Assembly Instructions: 1611 – Solenoid Big Ace X MHT Inlet – 24 VACLink:

Assembly Instructions: 1611B – Solenoid Ace X MHT Inlet – 24 VACLink:

Assembly Instructions: 2673 – Solenoid Big Ace X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 2673B – Solenoid Ace X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 2948 – AT Big Ace X MHT InletLink:

Assembly Instructions: 2949 – AT Big Ace X 3/4″ MNPT InletLink:

Assembly Instructions: 2950 – Solenoid AT Big Ace X MHT Inlet – 24 VACLink:

Assembly Instructions: 2951 – Solenoid AT Big Ace X 3/4″ MNPT Inlet – 24 VACLink:

Assembly Instructions: 1807-6R – Big Ace 5.5″ / 14 CM Average Reduction – RightLink:

Assembly Instructions: 1807-6L- Big Ace 5.5″ / 14 CM Average Reduction – LeftLink:

Assembly Instructions: 1807B-6R – Ace 5.5″ / 14 CM Average Reduction – RightLink:

Assembly Instructions: 1807B-6L – Ace 5.5″ / 14 CM Average Reduction – LeftLink:

Assembly Instructions: 1958-6 – Big Ace 5.5″ / 14 CM Average Reduction – No Riser TubeLink:

Assembly Instructions: 1958B-6 Cage Slope Neutralizer Assembly InstructionsLink:

Assembly Instructions: 1958B-6 – Ace 5.5″ / 14 CM Average Reduction 3/4 No Riser TubeLink:

Assembly Instructions: 1920-4 – Big Ace 4.25″ / 10.8 CM Average ReductionLink:

Assembly Instructions: 1920B-4 – Ace 4.25″ / 10.8 CM Average ReductionLink:

Assembly Instructions: 3825 – Ace – Aluminium ProfileLink:

Assembly Instructions: 3826 – Big Ace – Aluminium ProfileLink:

Assembly Instructions: 3827 – Ace – Aluminium ProfileLink:

Assembly Instructions: 3828 – Big Ace – Aluminium ProfileLink:

Assembly Instructions: 2930 – Big Ace X MHT OutletLink:

Assembly Instructions: 2931 – Ace X MHT OutletLink:

Assembly Instructions: 2629 FLOOR END ASSEMBLY: ACE X 3/4 MNPT OUTLET Assembly InstructionsStrict adherence to good management practices throughout the poultry operation, especially the watering system, is the only way producers can reduce the impact of respiratory disease on their flocks and profit.

Managing poultry barn environment key to controlling respiratory diseaseMany producers are not aware of the important role the watering system has in the feed conversion process.

Managing your watering system to improve feed conversionHow proper watering system setup and management can overcome the challenges of sloped floors.

When you can’t be on the levelWatering System automation has enabled producers to reduce labor costs and improve productivity.

Automated watering systems improve layer producers’ bottom linesWhat is the best way to measure the effectiveness of your watering system? Dont be fooled by some common misunderstandings in this important area. This brochure helps you base your evaluation on the only thing that really matters performance.

Performance MattersCompatibility: Clip-On Brackets to Big Z and Clip-On Saddles

GL1007Compatibility: Clip-On Brackets to TL Saddle

GL1008Drinker Manufacturing Date Codes

GL1009Square Pipe to Big Ace & 1″ PVC Fittings

GL1017Solenoid Flush Valve Field Repair & Maintenance

GL1023Recommended Drain Hose Set Up Into Holding Tank

GL1027Filter Setup for Cage Operation

GL1030Non-Recommended Drain Hose Setup

GL1031Water Supply Setup: 3/4″

GL1033Water Supply Setup: 1″

GL1034Water Supply Setup: 1 1/2″

GL1035Actual Size: Ace, Big Ace & Big Z Pipes

GL1038Ziggity Aktive Drinker interface with Val nipple saddles

GL1043Recommended Spraying Procedures: TL Start Grow Systems

GL1045Warning: Never Use Pliers on Ziggity Drinkers

GL1052Installation: Preventing Support Pipe Separation

GL1055Field Fix: Riser Tube Cap

GL1056Installation: Cord Adjuster

GL1057Field Fix: Slope Neutralizer

GL1058Old Versus Current Aktive Drinkers: Visual Differences

GL1060Proper gaping instructions – Ziggity pipe connectors

GL1068Field Fix: loose floor end assemblies

GL1069Pipe Connector to Pipe Interface: 260, 896 & 2672

GL1070Water Capacity for Ziggity Drinker Pipes and Water Supply Pipes.

GL1074Installation Instructions: Clip-On Saddles

GL1079Installation Instructions: Bracket Placement for Floor Watering Systems

GL1080Installation Instructions: Regulator & End Assembly to Big Ace / Big Z / Ace Pipe

GL1081Regulator adjustment knob conversion to adult turkey regulator

GL1084O-Ring Guide for various Ziggity parts

GL1085Installation Instructions: Heavy Duty Anti-Roost Cable

GL1087Riser Tube Cap Alternative Assembly For Low Pressure Flushing (1 Bar / 15 PSI Or Less)

GL1089Installation Instructions: Clip-On Saddle Adapters

GL1090Note gain per day and feed conversion. Broiler performance that crosses State lines.

Georgia Results – 1We note a pattern here – do you?

Georgia Results – 2Ditto

Georgia Results – 3Japan Results – 1

Japan Results – 2

Japan Results – 3

Performance near the top.

Maryland Results – 1Roaster program results.

Maryland Results – 2More roaster program results.

Maryland Results – 3Last of three roaster program results.

Maryland Results – 4Still more roaster results – second location

Maryland Results – 5And still more roaster results.

Maryland Results – 6Broilers prefer sanitary water – they respond with better results

Max3 versus catch cup systemsThese broiler result truly cross state lines.

Mississippi Results -1Simply better in all categories and a day younger

Mississippi Results – 2Only 9 points better in FCR.

Mississippi Results – 3Even with slightly lower weights FCR’s were so much lower the grower ranked number one for the week!

Mississippi Results – 4Note the difference in daily weight gain.

Mississippi Results – 5More of the same in Mississippi!

Mississippi Results – 6Ditto

Mississippi Results – 7Go old Miss

Mississippi Results – 8We leave Mississippi on a high note!

Mississippi Results – 9Note better performance in every category.

More Max3 versus catch cup systemsFour identical houses. Two with Ziggity Max3 and two with Ziggity Gold drinkers. (Moderate versus high dynamic flow drinkers) Production cycle nr.1

North Carolina Field Test – Max3 versus Gold 1/4Second out of four consecutive broiler production cycles.

North Carolina Field Test – Max3 versus Gold 2/4Third our of 4 consecutive broiler production cycles.

North Carolina Field Test – Max3 versus Gold 3/4The final comparative performance results.

North Carolina Field Test – Max3 versus Gold 4/4Note the difference in feed conversion rate.

North Carolina Results -1Bigger birds and a much lower feed conversion rate compared against all birds processed that same week.

North Carolina Results – 2Again bigger birds and lower feed conversion rate.

North Carolina Results – 3Broiler performance comparison against the average for the week and previous 5 growouts with older high flow Ziggity drinkers.

North Carolina Results – 4Note weight gain per day and FCR.

North Carolina Results – 5Two days younger yet heavier and with a better feed conversion rate of only 12 points better.

North Carolina Results – 6More of the same from the great State of North Carolina.

North Carolina Results – 7Solid Performance!

Northeastern Results – 1Again!

Northeastern Results – 2Solid results!

Texas Results – 1More results for the state of Texas

Texas Results – 2Younger birds yet heavier and with a lower FCR – go figure!

Texas Results – 3And always that improvement in FCR.

Texas Results – 4First of four consecutive growouts on a heavy bird program.

USA Heavy Broiler Producer 1/4Second of four growouts. The numbers speak for themselves.

USA Heavy Broiler Producer 2/4More of the same!

USA Heavy Broiler Producer 3/4Last but certainly not least!

USA Heavy Broiler Producer 4/4It is almost impossible to overemphasize the importance of water to poultry flocks

The role of water in the life of a chickenProduct bundling may provide producers with a one-time savings when building a new poultry house. However, that bundle of products may result in loses over the long term.

Product bundling not in producers’ best interestsZiggity is the only company whose sole focus is on poultry watering.

Ziggity focuses on maximizing system, litter and bird performanceElevated levels of ammonia in the poultry house can result in a wide range of problems for poultry producers

Ammonia in the poultry house sabotages production; can impact poultry workers’ healthBiofilm is an often overlooked and misunderstood threat to poultry flocks

Poultry farmers often overlook biofilm growing in watering systemThe better you understand how and why birds drink water, the better you can provide for their needs and produce more profitable flocks.

Understand broiler drinking behavior to achieve better flock performanceFive ways to maximize the benefits of an enclosed watering system.

Maximizing the benefits of enclosed watering systemsGrowing a successful and profitable broiler flock requires diligent planning and management especially in preventing diseases and other conditions that harm the birds.

Planning necessary to prevent disease in poultry flockGravity-controlled water tanks provide an excellent solution to the challenges of unreliable electric power and intermittent water supply

Solutions to the five most common challenges found in gravity-controlled water tanksWater quality from wells plays an important role in flock performance.

Ignore your well at your own riskThe route to improving flock performance lies in good litter management.

Good litter management ensures flock performanceCommon mistakes producers make concerning their watering systems.

Five watering mistakes that can hurt productionThe watering system and how the farmer manages it determine many of the conditions in a parent stock operation.

Watering system critical in parent stock operationReturn on investment, not the up-front cost of a new barn, is the most important aspect to consider when building a new facility

Quality components, not special prices, required when building a new poultry barnMany of the decisions a poultry farmer is asked to make can carry unintended consequences that can hurt the bottom line

It may sound like a good idea, but is it really?